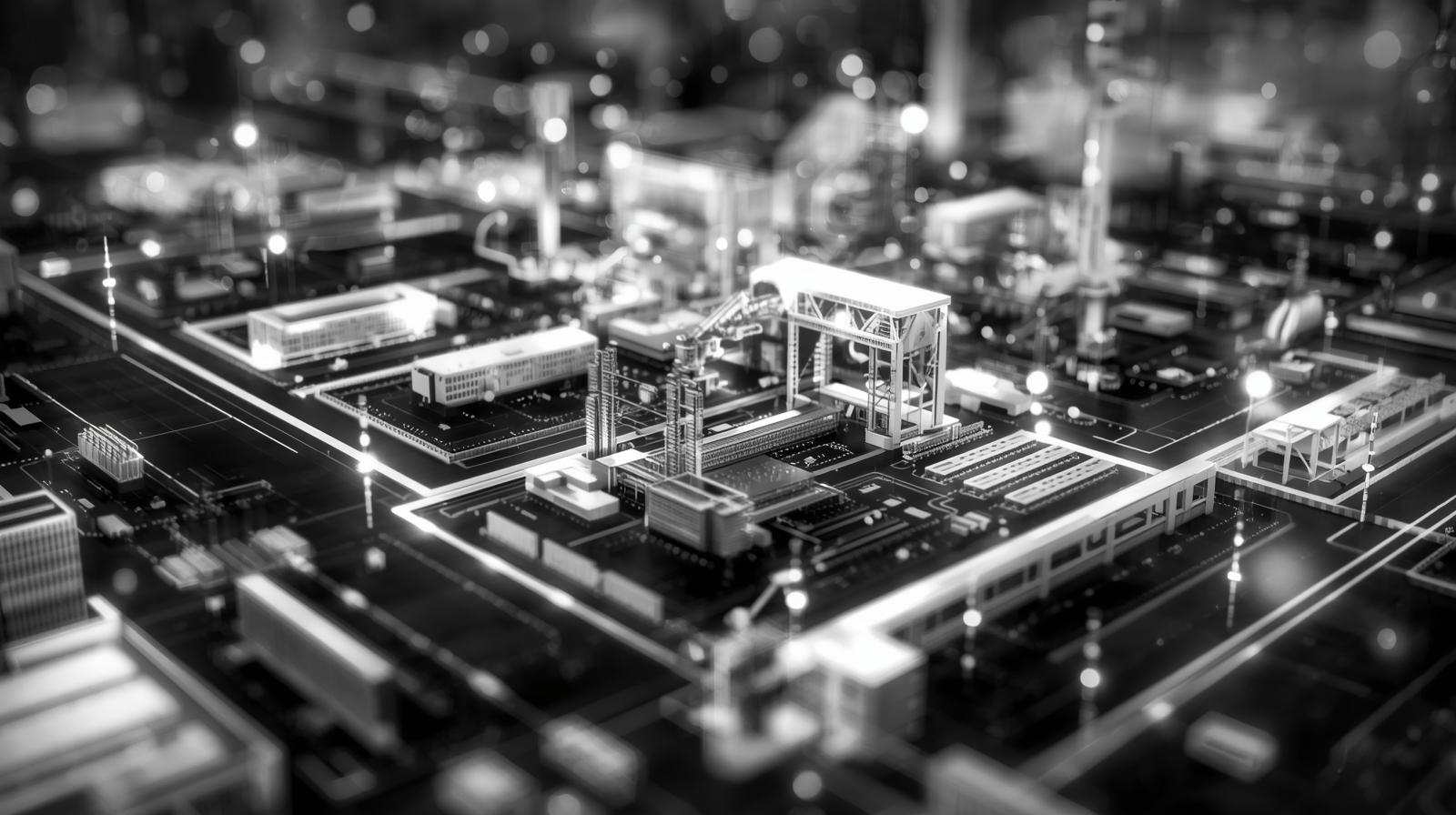

BIM in factory planning: Holistic approaches from the FaBIM research project

by Franziska Wagner & Marcel Potthoff | September 24th, 2025

The factory of the future poses enormous challenges for companies and planners: increasing demands for sustainability and energy efficiency, shorter product life cycles, and a dynamic market environment. Traditional methods are increasingly reaching their limits—projects take too long, become more expensive than planned, and often fail to meet their original goals.

This is precisely where Building Information Modeling (BIM) offers completely new opportunities in factory planning. BIM is much more than a digital 3D model – it is a collaborative method that connects planning, construction, and operation via a shared database. While the construction industry is already benefiting from BIM in larger projects, the integration of BIM into factory planning is still in its infancy. This is precisely where the FaBIM research project on digital factory planning comes in.

Key challenges in production and factory planning

Planning modern factories is more complex today than ever before. In addition to sustainability goals and increasing pressure to create climate-neutral production facilities, global supply chain crises and volatile markets are exacerbating the situation. Companies must adapt their production systems at ever shorter intervals and need buildings that are adaptable and future-proof.

In addition, the shortage of skilled workers makes it difficult to implement large construction projects. What’s more, hardly any other construction project is as interdisciplinary as factory planning:

- Architects think in terms of building structures,

- structural engineers in terms of static and dynamic loads,

- building services engineers in terms of supply networks,

- factory planners in terms of material flows,

- operators in long-term economic efficiency,

- investors in costs and adherence to deadlines,

- production teams in efficiency and flexibility.

This multitude of participants inevitably leads to interfaces, conflicting goals, and communication problems. Information is often recorded multiple times, lost, or reaches the right places too late. Even small coordination errors can have serious consequences: a machine does not fit on the intended foundation, or media connections are in the wrong place and have not been sufficiently dimensioned.

This is precisely where BIM comes in. Data models, standardized information flows, and a central data environment/common data environment (CDE) create a common language for all project participants. This makes it possible to involve architects, structural engineers, factory planners, operators, and investors at an early stage, to make their requirements transparent, and to defuse conflicting goals as early as the planning phase. BIM thus not only ensures technical precision, but also better collaboration and interoperability between all parties involved.

FaBIM: The research project and its partners

To take advantage of these opportunities, the FaBIM research project was launched in 2022. It brought together partners from research, software development, consulting, and planning. Participants included Fraunhofer IGCV, CONTACT Software, ifp consulting, Kohlbecker, and us, BIM-GLW. Together, we developed methods and tools that enable consistent and holistic factory planning.

To structure the work, the project was divided into three work packages (WP):

WP1: Development of an Information Delivery Manual (IDM)

The aim was to define uniform requirements for the exchange of information across all project participants and phases. The ILH – known internationally as the Information Delivery Manual (IDM) – specifies what information is to be provided, when, in what quality, and by whom. It thus creates the basis for a consistent, efficient flow of information.

WP2: Design of a common data environment (CDE)

This work package formed the technical foundation. The aim was to develop a central digital platform in which all relevant life cycle data could be consistently recorded, managed, exchanged, and visualized.

AP3: Continuous potential analysis

In order to make the added value of the developed approach measurable, methodological and economic potentials were continuously identified, evaluated, and documented.

This clear structure made it possible to combine scientific approaches with practical requirements and develop a solution that adds value both in research and in real-world projects.

Construction and factory planning: the convergence of two disciplines

Building Information Modeling has been established in the construction industry for several years. Architects and specialist planners use BIM to implement construction projects more efficiently and collaboratively. BIM models are created digitally, processes can be better coordinated, collisions can be detected early on, and addenda can be reduced.

In factory planning, on the other hand, traditional methods still often dominate. This involves machine layouts, material flows, storage technology, and logistics. Many decisions are based on isolated solutions in simulation software. A consistent, standardized exchange of information rarely exists.

Yet construction and factory planning are closely interlinked:

- The supporting structure of a building must be able to bear the loads of the planned machines.

- The building services must provide media such as compressed air, water, or electricity exactly where they are needed for production.

- The building envelope and supporting structure must be flexible enough to allow for later adjustments to the production layout.

With BIM for factory planning, these dependencies can be identified at an early stage. Digital twins allow construction and production models to be merged and interfaces between disciplines to be clearly defined.

To make the potential tangible, the project first collected, evaluated, and consolidated over 300 use cases from construction and factory planning. In the end, four central scenarios remained:

- Factory planning in existing buildings (brownfield)

- Coordination and collision checking

- Digital twin

- Inventory assessment

These use cases formed the core for the development of processes and methods. They clearly demonstrated the importance of a consistent data flow across all disciplines.

Seamless collaboration through intelligent interface management

A factory construction project brings numerous stakeholders together: architects, civil engineers, building services engineers, factory planners, operators, investors, and many more. Every interface is a potential source of error—information can be lost, duplicated, or transmitted too late.

That’s why we at FaBIM paid special attention to interface management.

The Information Delivery Manual (IDM) specified which party would provide which information in which form and at what time. This involved not only traditional documents such as planning contracts or cost estimates, but also, in particular, the precise definition of BIM models.

The information requirements are significantly more differentiated, especially for BIM models:

- Specific requirements for the information content were defined for critical components, such as foundations, media connections, or special production facilities.

- Two dimensions of detailing were distinguished: Level of Geometry (LOG) for the geometric level of detail and Level of Information (LOI) for the alphanumeric attributes.

This structure ensured that the BIM models supplied actually covered the requirements of the other discipline.

At the same time, a CDE was set up. It formed the technical basis for managing information consistently and in a version-secure manner. Role-based access rights ensure that each participant only sees the relevant content, but at the same time always has access to the latest data.

The combination of IDM and CDE proved to be key: while the IDM defined the rules, the CDE ensured their practical implementation. This resulted in transparent, reliable, and efficient information management throughout the entire project.

Paths to the future: Conclusion and research perspectives

FaBIM has impressively demonstrated the enormous potential of BIM in factory planning. Processes become more transparent, coordination more efficient, and error rates drop noticeably. Especially in complex projects, builders, operators, and planners alike benefit from clearly defined information management and a shared database.

At the same time, there is still a need for research: the standardization of relevant project documents has not yet been completed, the integration of sustainability indicators and energy data is still in its infancy, and the consistent use of the digital twin throughout the entire life cycle opens up further opportunities.

One thing is clear, however: the factory of the future will be digitally planned, built, and operated. With projects such as FaBIM, we are laying the foundations for this—in a practical, interdisciplinary manner and with a clear view of the added value for builders and users.

Together with Building Information Cloud GLWG GmbH, we are continuing to explore this topic in greater depth. In an upcoming article, we will focus on factory planning-specific quality checks, such as verifying the stability of production systems. In doing so, we will demonstrate how BIM can be used not only for information exchange, but also for ensuring the highest quality standards in factory planning.

Let's shape the digital revolution together. Now is the time to rethink!

Discover our reference projects and learn how our collaboration creates tangible added value—for all decision-makers who want to implement construction projects digitally, sustainably, and efficiently.

Do you have your own ideas or approaches? We welcome new partnerships.